PRODUCTS

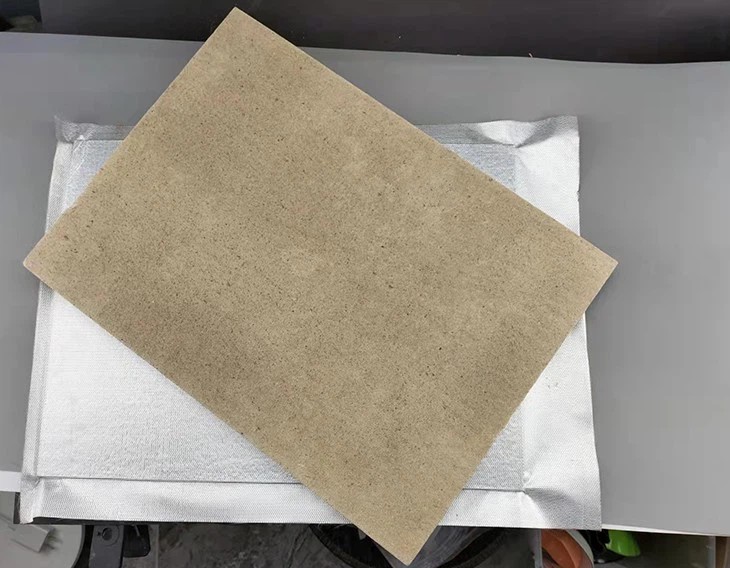

Vermiculite Board

Products Description The use of vermiculite boards in fireplace linings originated in South Korea. Foreign countries have extremely strict requirements on health, heat preservation, and fire protection. In terms of environmental protection, they will not release harmful gases and other substances that pollute the environment at high temperatures. As a fireplace lining, the fireplace vermiculite board mainly uses expanded vermiculite as the main raw material. There is no carbon and sulfur in the molecular composition, and it will not produce harmful gases such as CO2 and SO2 that affect the atmo

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Vermiculite Board Details

Products Description

The use of vermiculite boards in fireplace linings originated in South Korea. Foreign countries have extremely strict requirements on health, heat preservation, and fire protection. In terms of environmental protection, they will not release harmful gases and other substances that pollute the environment at high temperatures. As a fireplace lining, the fireplace vermiculite board mainly uses expanded vermiculite as the main raw material. There is no carbon and sulfur in the molecular composition, and it will not produce harmful gases such as CO2 and SO2 that affect the atmosphere, and will not cause harm to the human body.

Features

1. Fire & Heat Resistance: Vermiculite board has a high melting point, making it an excellent natural fire and heat resistant material.

2. Soundproofing: It is a great soundproofing material, as it can block sound waves and reduce noise levels in a room.

3. Lightweight: Despite being a strong material, it is incredibly lightweight. This makes it easy to install and transport.

Technical Sheet

| Grade | V-1200 | |

| Bulk Density(kg/m³) |

1150-1300 |

|

|

Max Service Temperature(℃) |

1200 | |

|

Modulus of Rupture(EN993-6:1995)(MPa) |

>2.8 |

|

|

Chemical Analysis |

SiO2(%) |

48-54 |

|

Al2O3(%) |

10-25 |

|

|

MgO(%) |

10-21 | |

|

K2O(%) |

5-9 |

|

|

CaO(%) |

≤3 |

|

Application

1. Vermiculite board is a type of fireproof board that can be used in fireplaces.It is often used for lining the interior wall of the firebox, and for fireproofing the area around the fireplace.

2.It is a lightweight, fire-resistant material that is often used in kilns to protect walls and floors from heat and flames. It is used in kilns as a lining or insulation board, as well as a backing board for shelves and other kiln accessories.

3.They are typically used in fire doors to provide a fire rating of up to four hours. When used in fire doors, the boards provide a barrier that prevents the spread of fire, smoke, and toxic gases. The boards can also provide insulation, helping to reduce heat transfer into the rest of the building.