PRODUCTS

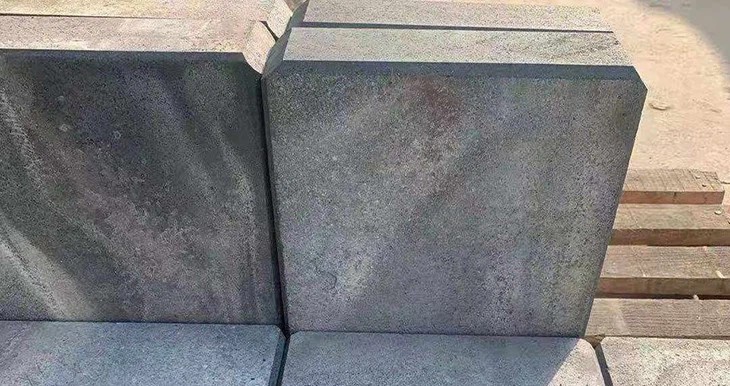

Silicon Carbide Push Plate

The silicon carbide push plate is mainly composed of silicon oxide and silicon carbide. The oxidation of silicon carbide is more obvious above 1300 ℃. It is suitable for some low-end manufacturing fields or fields with low furnace temperature. The current large application field is the positive electrode of lithium battery. Material pusher kiln, inorganic powder calcination pusher kiln, etc.

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Silicon Carbide Push Plate Details

Products Description

Silicon carbide push plate is made of high-purity silicon carbide ceramic material, which has high hardness, high strength, high temperature stability and excellent wear resistance. It also has excellent chemical stability and good resistance to corrosive media such as acids and alkalis.

It has a lower density compared to metal materials, thus enabling lightweight designs. Despite this, it is very strong, capable of withstanding high pressure and mechanical stress, and is suitable for applications requiring high strength and lightweight construction.

Features

1.Excellent fire resistance: It has excellent fire resistance, can work stably for a long time at high temperature, and will not be corroded by flame, high temperature gas and molten substances

2.Chemical corrosion resistance: It has good resistance to corrosive media such as acid and alkali. In some kilns or chemical reactors that need to deal with corrosive substances, silicon carbide push plates can provide effective protection.

3.Excellent thermal conductivity: Silicon carbide push plate has excellent thermal conductivity, which can transfer heat quickly and achieve uniform heating or cooling.

Application

1.High-temperature furnaces: Silicon carbide push plates are widely used in high-temperature furnaces, such as high-temperature sintering furnaces, melting furnaces, and steelmaking furnaces. Due to its high temperature stability, fire resistance and chemical resistance, it can withstand extremely high temperatures and corrosive media, providing reliable protection and support.

2.Ceramic Industry: It plays an important role in the ceramic industry. It can be used as lining, support and protective layer of kilns and sintering furnaces for sintering and heat treatment processes of ceramic materials.

3.Chemical industry: Silicon carbide push plate is widely used in chemical industry due to its excellent corrosion resistance. It can be used for the lining and partition of chemical reactors, acid-base storage tanks, distillation units and other equipment to resist the erosion of corrosive media.

4.Environmental protection field: It has application potential in the field of environmental protection. It can be used in high-temperature gas filters and dust removal devices to filter and trap solid particles in high-temperature flue gas and purify exhaust gases.