PRODUCTS

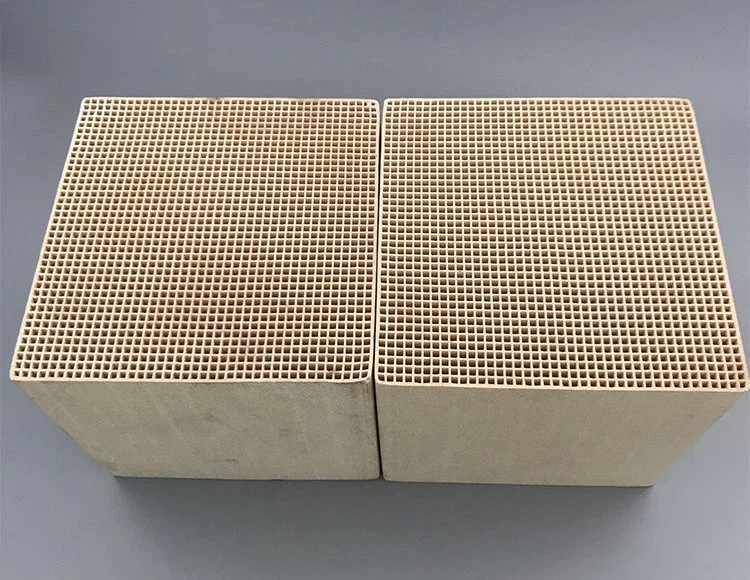

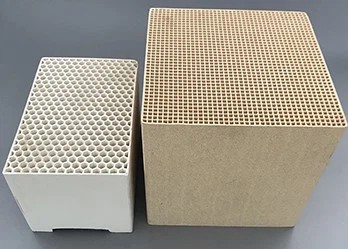

Honeycomb Ceramics

Honeycomb ceramics is a kind of porous industrial ceramics. Its internal structure is many through parallel channels. These honeycomb units are divided by lattice-like thin partitions of different shapes.

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Honeycomb Ceramics Details

Products Description

Since the advent of honeycomb ceramics, the development tends to be persified. The main materials are cordierite, aluminum titanate, silicon carbide, zirconia, silicon nitride, corundum, mullite, quartz, etc., and can also be two or more of them. made. At present, according to the application field, it can be pided into heat storage body, catalyst carrier, filter material, etc.

According to different conditions of use, select raw materials with different properties. According to the shape of the hole, it can be pided into square, regular hexagon, circle, triangle, etc. The shape of the hole has an impact on the specific surface area and opening rate of the honeycomb ceramics.

Features

1.Strong adsorption capacity

2.Excellent stomatal structure

3.Good thermal stability

4.Good wear resistance

5.Low density

Technical Sheet

| Project | 100*100*50MM | |

|

Thermal expansion coefficient(in/inK) |

1.5-1.8 |

|

|

Specific heat capacity(J/kgK) |

850-1000 |

|

|

Material density(kg/m3) |

1800-2000 |

|

| Bulk density(kg/m3) | 500-680 | |

|

Thermal shock resistance (K) |

Max 500 |

|

|

Water absorption(%) |

20-25 | |

|

Max working temperature(℃) |

1300 |

|

|

Chemical Composition(%) |

Al2O3 |

30-38 |

|

SiO2 |

45-55 | |

|

MgO |

12-14 | |

|

Fe2O3 |

<1 | |

|

CaO+K2O+Na2O |

<1 | |

Application

1. Catalyst carrier

When used as a catalyst carrier, it is mainly used in automobile exhaust purification, boiler exhaust denitrification (NOx), industrial exhaust deodorization, removal of toxic and harmful gases, etc.

Catalyst supports for automobile exhaust purification are mainly cordierite honeycomb ceramic supports coated with γ-Al2O3.

2. Refractory kiln furniture

The quality of extruded honeycomb ceramic kiln furniture is 60%-75% lighter than traditional kiln furniture, and the heat transfer is rapid, which can realize fast firing. When using it to fire ferrite or other electronic ceramics, it is beneficial to improve the performance of the product.

3. Wall flow filter

Porous and thin-walled can filter and purify carbon particles in diesel engine gas exhaust (about 500°C).