PRODUCTS

High Alumina Brick

High Alumina Brick is a neutral refractory material with an alumina content exceeding 48%. It is formed by calcining alumina and other raw materials with high alumina content. It has good slag resistance and can be used for the lining of steel-making

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

High Alumina Brick Details

High Alumina Brick is a neutral refractory material with an alumina content exceeding 48%. It is formed by calcining alumina and other raw materials with high alumina content. It has good slag resistance and can be used for the lining of steel-making electric furnaces, glass melting furnaces, cement rotary furnaces, etc. These bricks are used in various industrial furnaces and high temperature areas to extend the life of the furnace.

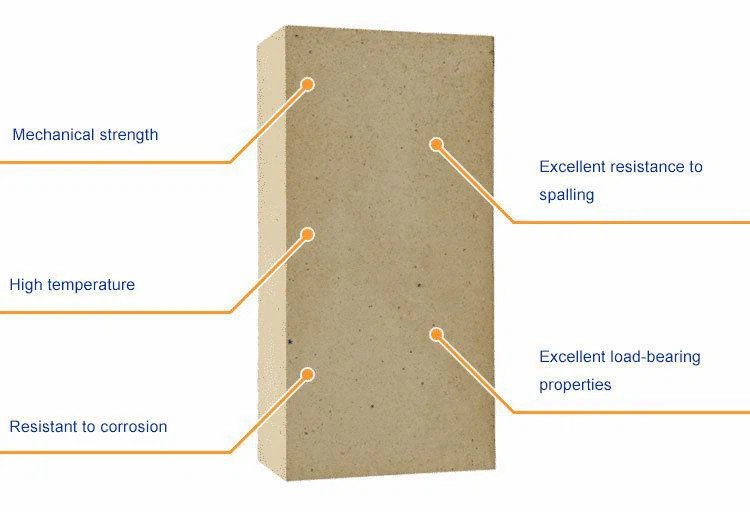

Features

1. Fire resistance

High Alumina Brick has a higher refractoriness than clay bricks and semi-silica bricks, reaching 1750-1790°C, which is a high-grade refractory material.

2. Load softening temperature

Because the high Al2O3 in high-aluminum products has less impurities and fusible glass body, the load softening temperature is higher than that of clay bricks

2. Slag resistance

High alumina brick contains more Al2O3, which is close to neutral refractories and can resist the erosion of acid slag and alkali slag.

Applications

High Alumina Brick can be applied in the following areas:

1. Steel manufacturing industry: blast furnace, hot blast furnace (furnace), pellet furnace, ladle, ladle, tundish, heating furnace, soaking furnace, heat treatment furnace, refining furnace, heating furnace, metal stirring furnace, annealing furnace, cupola , Electric arc furnace, induction furnace, AOD furnace, VOD furnace and other technical equipment.

2. Non-ferrous metal industry: smelting furnace, refining furnace, reverberatory furnace, converter.

3. Building materials industry: cement kiln, glass kiln, ceramic kiln, lime kiln, automobile kiln, tunnel kiln

4. Energy and incineration: coke oven, ordinary boiler, power generation, power generation, boiler, circulating fluidized bed boiler, electric furnace, charcoal injection furnace, garbage incinerator.

5. Other: petrochemical industrial furnace.

Physical And Chemical Indicators

|

Brand Properties |

SK-40 |

SK-38 |

SK-37 |

SK-36 |

SK-35 |

|

|

Refractoriness (SK) |

40 |

38 |

37 |

36 |

35 |

|

|

Apparent Porosity (%) |

22 |

23 |

23 |

23 |

23 |

|

|

Bulk Density (g/cm3) |

2.65 |

2.40 |

2.35 |

2.30 |

2.25 |

|

|

Cold Crushing Strength(MPa) |

70 |

52 |

50 |

45 |

40 |

|

|

Thermal Linear Expansion(%) @1000deg |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

Permanent Linear Change(%) @1400degx2hrs |

±0.2 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

|

|

Refractoriness under Load (ºC) @0.2MPa |

1,530 |

1,500 |

1,450 |

1,420 |

1,380 |

|

|

Chemical Composition(%) |

Al2O3 |

80 |

72 |

60 |

50 |

45 |

|

Fe2O3 |

1.8 |

2.0 |

2.0 |

2.0 |

2.0 |

|