PRODUCTS

Crucible

The crucible is a container or melting tank made of extremely refractory materials, such as clay, graphite, china clay and other inorganic non-metallic materials or relatively difficult-melt metal materials.

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Crucible Details

Products Description

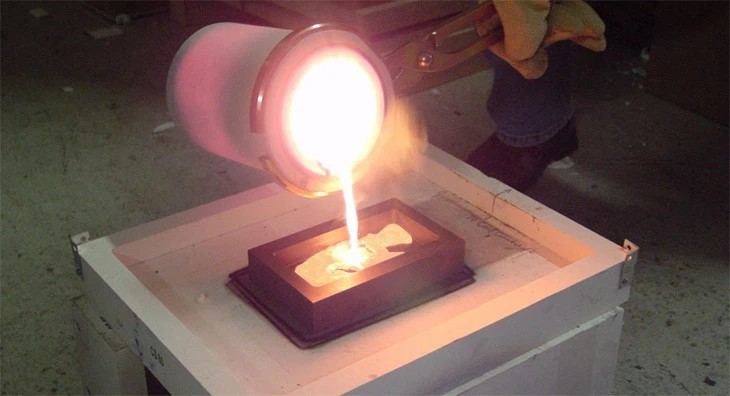

The crucible is a refractory container used to melt and smelt metal liquid or the chemical reaction of substances. Its general shape is like a jar for smashing garlic. It is basically a cylinder with a large top and a small bottom. It can be melted or melted by heating the crucible. Extracting some required substances is also an important tool for chemically reacting some substances through heating.

Refractory materials used in crucible manufacturing include various types of ceramics, such as alumina (aluminum oxide), silicon carbide, graphite, zirconia, and magnesia. These materials maintain their structural integrity at elevated temperatures, making them suitable for containing molten metals, glass, slag, and other high-temperature substances.

Features

1.Thermal Shock Resistance:Refractory materials used in crucibles have good resistance to thermal shock, allowing them to handle rapid temperature changes without cracking or breaking.

2.Mechanical Strength:While refractory materials can be brittle, crucibles are designed with sufficient mechanical strength to handle the weight of their contents and to resist cracking or deformation during use.

3.Chemical Stability:These crucibles are resistant to chemical reactions with the materials they contain, which is crucial when working

Application

1. Metallurgy:Refractory crucibles are commonly used in metallurgical processes such as melting, casting, and alloying of metals like iron, steel, aluminum, copper, and precious metals.

2. Glass Manufacturing:In the glass industry, crucibles are employed to melt and shape glass for various applications, including laboratory glassware, optical components, and artistic glassware.

3. Foundries:Crucibles are vital components in foundries for melting and casting non-ferrous metals like bronze, brass, and other alloys.

4. Ceramics Industry:Refractory crucibles are used for firing ceramics and pottery at high temperatures, ensuring uniform heat distribution and controlled firing cycles.

5. Chemical Processing:In chemical laboratories and industrial settings, refractory crucibles are used for high-temperature reactions, calcination, and other processes involving aggressive chemicals.