PRODUCTS

Ceramic Lining Bricks

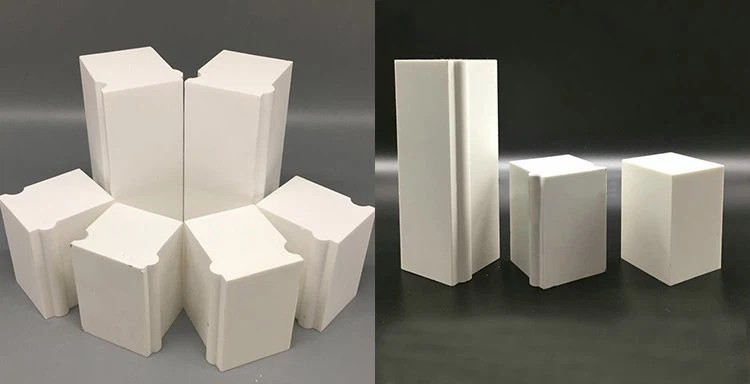

The ceramic lining brick is pressed and formed by a bidirectional hydraulic press and sintered in a high temperature natural gas kiln. The inner and outer structure of wear-resistant ceramic lining bricks is uniform and consistent and has been tested

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Ceramic Lining Bricks Details

Product Description

Ceramic lining bricks have the characteristics of high strength, high fracture toughness, low wear, good regularity, impact resistance, abrasion resistance, scientific formulation, dry pressing and high temperature firing. The Mohs hardness is 9, second only to diamond. The construction is convenient, the theoretical wear resistance is 300 times that of manganese steel, and the service life can generally reach 10 times.

Features

Ceramic lining brick features:

1.The main component is high-quality alumina with a content of 92%, with high purity, which can greatly reduce the pollution to the grinding materials.

2.Good wear resistance, wear resistance is 266 times that of manganese steel, effectively prolonging the service life of machinery and equipment.

3.The slurry produced by the wear-resistant ceramic lining brick and high-alumina ball is fine.

4.has the characteristics of corrosion resistance, high density and high mechanical strength.

Application

Wear-resistant ceramic lining brick is an anti-wear product embedded in the inner wall of the ball mill. It can also be used in refractory materials, electronics, ceramics, and high-temperature kilns, which can effectively improve grinding efficiency, reduce grinding costs, and reduce product pollution.

Physical And Chemical Indicators

|

Brand Properties |

ALB-92 |

ALB-92S |

ALB-95 |

|

|

Al2O3(%) |

≥92 |

≥92 |

≥95 |

|

|

Bulk density(g/cm3) |

≥3.65 |

≥3.68 |

≥3.68 |

|

|

Wear Loss(%) |

≤0.01 |

≤0.008 |

≤0.01 |

|

|

Hardness(Mohs) |

9 |

9 |

9 |

|

|

Water Absorption(%) |

≤0.01 |

≤0.01 |

≤0.01 |

|

|

Color |

white |

white |

white |

|

|

Size |

Length(mm) |

(W1) Width (mm) |

(W2) Width (mm) |

(H) Height (mm) |

|

End Flat Brick |

150 |

50 |

||