PRODUCTS

Ceramic Fiber Wool

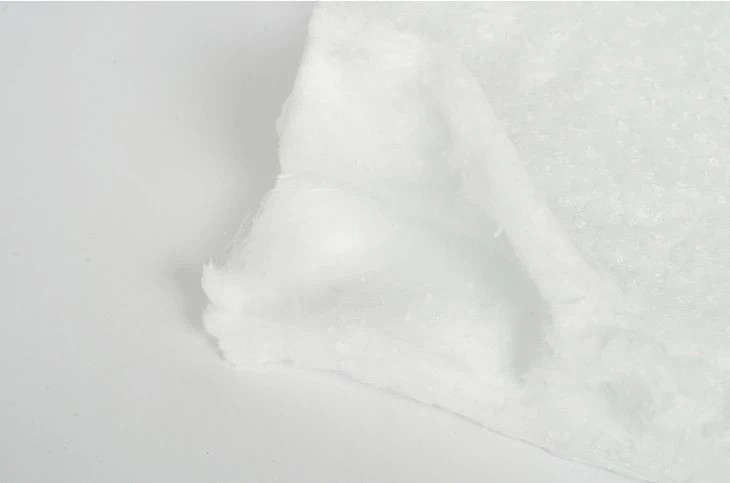

The fiber surface of ceramic fiber wool is smooth and cylindrical, and the cross section is usually circular. Its structure is characterized by high porosity (generally greater than 90%), and large pore size and specific surface area. Since the air in the pores has a good heat insulation effect, the size of the pores in the fiber and the properties of the pores (open pores or closed pores) have a decisive impact on its thermal conductivity. In fact, the internal structure of ceramic fibers is a kind of A mixed structure composed of solid fibers and air, whose microstructure is characterized by

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Ceramic Fiber Wool Details

The fiber surface of ceramic fiber wool is smooth and cylindrical, and the cross section is usually circular. Its structure is characterized by high porosity (generally greater than 90%), and large pore size and specific surface area. Since the air in the pores has a good heat insulation effect, the size of the pores in the fiber and the properties of the pores (open pores or closed pores) have a decisive impact on its thermal conductivity. In fact, the internal structure of ceramic fibers is a kind of A mixed structure composed of solid fibers and air, whose microstructure is characterized by the existence of both the same phase and the gas phase in the form of a continuous phase.

Features

(1) The thermal conductivity is low, only 0.03 W/(m K) at room temperature, and 1/5 of clay brick at 1000 °C.

(2) The density of the product is small, generally between 64 and 500 kg/m3.

(3) The heat capacity is low, only 1/72 of refractory bricks and 1/42 of lightweight bricks.

(4) Good processing performance, soft and easy to cut fibers, strong continuity and easy winding.

(5) It has good sound absorption performance and can be used as a high-temperature sound-absorbing material.

(6) Good chemical stability, except for strong alkali, fluorine and phosphate, it is almost not corroded by chemicals.

(7) Good thermal shock resistance.

(8) The insulation performance is good, the volume resistivity at room temperature is 1×1013Ω·cm, and the volume resistivity at 800°C is 6×108Ω·cm.

(9) Ceramic fiber wool have high reflectivity to light waves with a wavelength of 1.8~6.0 μm

Applications

Ceramic fiber wool is usually processed into various styles of ceramic fiber products for selection in various industries. The most important use of ceramic fiber products is thermal insulation in high temperature environments. The application scope covers metallurgy, machinery, electronics, ceramics, glass, chemicals, automobiles, building materials, light industry, military industry, ships, aerospace and other fields.

At present, ceramic fiber products include blankets, felts, boards, paper, cloth, belts, ropes, coiled pipes, tiles, modules, special-shaped parts, plastics, spray coatings, smears, castables, etc.

Physical And Chemical Indicators

|

Brand Properties |

STD BULK |

HP BULK |

HZ BULK |

|

|

Chemical Composition(%) |

Al2O3 |

≥44 |

≥45 |

≥34 |

|

SiO2 |

≥52 |

≥54 |

≥50 |

|

|

Fe2O3 |

≤1.0 |

≤0.5 |

≤0.5 |

|

|

Na2O |

≤1.0 |

≤0.2 |

≤0.2 |

|

|

ZrO2 |

- |

- |

≥15 |

|

|

Specification Temp. (℃) |

1260 |

1260 |

1430 |

|

|

Shot content (%) |

≤15 |

≤15 |

≤12 |

|

|

Fiber Diameter(μm) |

3.5 |

|||