PRODUCTS

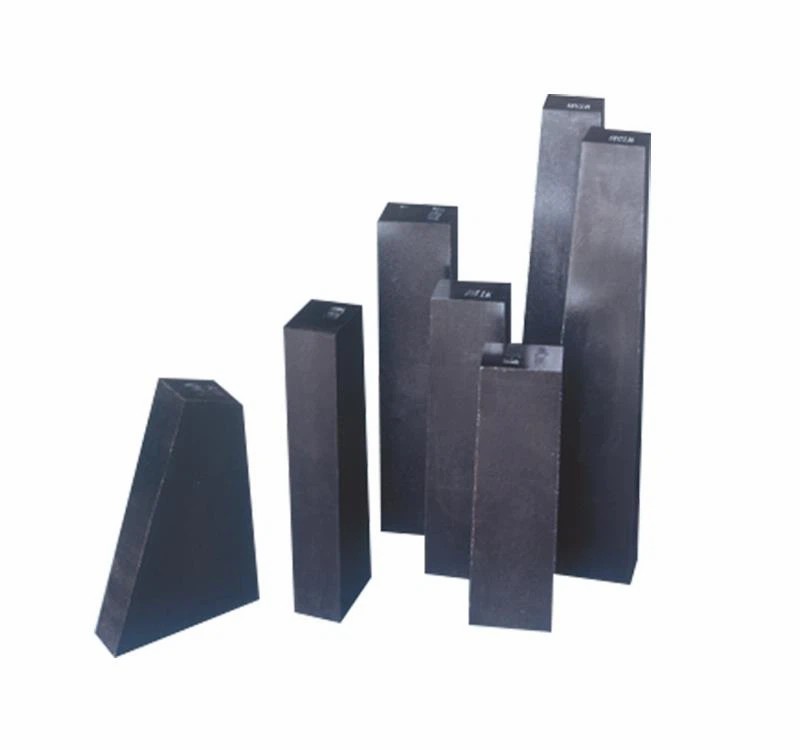

Al2O3 SiC C Brick

Al 2 O 3 SiC C brick is made from high-grade bauxite, fused alumina, silicon carbide and graphite as raw materials and resin as binder. It features excellent corrosion and erosion resistance and thermal shock resistance, and have high refractoriness under load. Al 2 O 3 SiC C brick refers to the non-burnt carbon composite refractory material that uses AL2O3, SiC and carbon raw materials as the main components and synthetic phenolic resin as the binder. The production of Al 2 O 3 SiC C mainly includes fused corundum, sintered corundum, alumina clinker, andalusite, silicon carbide, graphite and o

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Al2O3 SiC C Brick Details

Al2O3 SiC C brick is made from high-grade bauxite, fused alumina, silicon carbide and graphite as raw materials and resin as binder. It features excellent corrosion and erosion resistance and thermal shock resistance, and have high refractoriness under load.

Al2O3 SiC C brick refers to the non-burnt carbon composite refractory material that uses AL2O3, SiC and carbon raw materials as the main components and synthetic phenolic resin as the binder. The production of Al2O3 SiC C mainly includes fused corundum, sintered corundum, alumina clinker, andalusite, silicon carbide, graphite and other additives. In addition, a certain amount of fused magnesia is added to the matrix, so that the brick forms spinel during the application process, and has residual expansion properties, and improves the thermal strength, thereby enhancing the brick's corrosion resistance.It is mainly used for lining of hot metal pretreatment equipment such as torpedo-type mixed iron trucks and hot metal tanks. AL2O3 SiC C brick has excellent slag resistance and thermal shock resistance, as well as good erosion resistance and wear resistance. It is by far the most ideal lining material on hot metal pretreatment containers.

Production Process:

Adding carbon raw materials to the main alumina raw materials, adding a small amount of other raw materials such as silicon powder, SiC powder, aluminum powder, etc., using phenolic resin or asphalt as a binder, after batching, mixing , Isostatic pressing (or machine pressing), firing in a reducing atmosphere.

Features

High refractoriness.

Good spalling resistance and wear resistance.

Good corrosion resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Applications

Mainly used in pig iron ladle furnace,steel oxidation conversion furnace lining and tapping hole, high power electric furnace wall hot place, and outside the furnace refining furnace lining, ladle slag line parts and so on.

Specifications

Widely used throughout metallurgical industry

Physical And Chemical Indicators

|

Brand |

TC SZ |

TC MZ |

TC BI |

TC TR |

|

|

Apparent Porosity (%) |

7 |

8 |

8 |

9 |

|

|

Bulk Density (g/cm3) |

3.00 |

2.98 |

2.98 |

2.93 |

|

|

Cold Crushing Strength (MPa) |

55 |

50 |

45 |

45 |

|

|

Thermal Linear Expansion(%) @ 1,000℃ |

0.58 |

0.55 |

0.55 |

0.52 |

|

|

Refractoriness Under Load (℃) @0.2MPa |

1750 |

1700 |

1700 |

1650 |

|

|

Chemical Analysis (%) |

Al2O3 |

72 |

68 |

67 |

65 |

|

SiC |

11 |

10 |

10 |

10 |

|

|

FC |

13 |

12 |

11 |

10 |

|

|

Main Applications |

Torpedo & Iron Ladle |

||||