PRODUCTS

Type 1200 Nano Microporous Insulation Board

It is a new product made of specrl inorganic retractory nano powder and unigue nano technoloay. The therma conductivity of the product is smaller than that of stll air.

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Type 1200 Nano Microporous Insulation Board Details

[Product descoriotion]

It is a new product made of specrl inorganic retractory nano powder and unigue nano technoloay. The therma conductivity of the product is smaller than that of stll air. At high temperatures, its thermal insulation performance is 2.5 times better than thatof traditional fiber-based thermal insulation materials.

In the high temperature equipment with limited space and weight, the 1200 type nano thermal insulation material is the bestchoice, and has been widely used in various complex thermal equipment, solving many world thermal insulation problems.

[Packing]

Different packaging methods are used, such as bare board/POF heat shrinkable film/aluminum foil paper, etc, to meet theapplication needs in difterent fields. At the same time, in the process of preparation of this material, no adhesive ingredients are used, and the materials used are fully in line with various types of materials. Environmental requirements.

[Typical application]

Aluminum melting furnace, aluminum electrolytic cell,aluminum holding furnace, glass furnace, tempering furnace,roller kiln, tunnel kiln, pit furnace, heat treatment furnace,cracking furace, rescue cabin, lithium electric kiln, rotarykiln, etc.

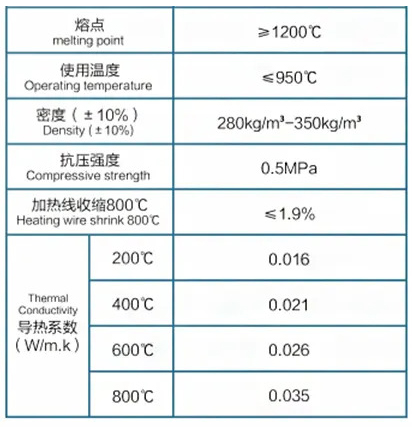

[Product parameters]