PRODUCTS

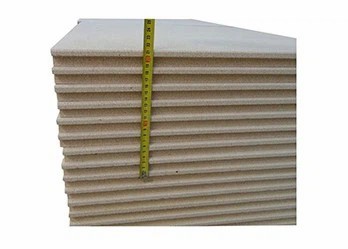

Cordierite-Mullite Board

Cordierite-mullite boards are sintered from mullite and cordierite. The mechanism is that cordierite has a much smaller thermal expansion coefficient than mullite due to its large gaps in the ring structure, and the matching of the expansion coefficients of the two makes the two-phase interface form fine cracks, preventing destructive cracks from forming. extended, thereby greatly improving the thermal stability performance.

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Cordierite-Mullite Board Details

Products Description

Cordierite-mullite board is fired with mullite as aggregate and cordierite as base material. Since cordierite has a (SiO2)n ring-shaped structure, there are large voids in this structure, so it has the characteristics of small thermal expansion coefficient, while mullite has a large thermal expansion coefficient, resulting in a mismatch between the expansion coefficients of the two materials, making the two materials.

The formation of fine cracks at the phase interface can effectively reduce the thermal stress caused by temperature changes, effectively avoid the spread of catastrophic cracks, and greatly improve the thermal stability of cordierite-mullite refractories; at the same time, because mullite The crystal has high refractoriness (melting point is 1810°C) and high mechanical strength (bending strength at room temperature is 49MPa), so using mullite as aggregate can effectively improve the high temperature strength of the shed.

Features

1. High temperature resistance: It can withstand extremely high temperatures, typically up to 1,400°C (2,552°F) They exhibit excellent thermal stability, maintaining their structural integrity even under rapid temperature changes.

2. Low thermal expansion: These boards have a low coefficient of thermal expansion, meaning they expand and contract minimally when exposed to temperature variations. This property helps to prevent cracking and deformation of the kiln furniture during thermal cycling.

3. Chemical inertness: Cordierite-mullite slabs are chemically inert, meaning they do not react with most chemicals or molten metals encountered in high-temperature processes.

Application

1. Kiln furniture: Cordierite-mullite boards are widely used as kiln furniture in industries such as ceramics, glass, and metallurgy. They provide a stable and heat-resistant platform for supporting ceramic ware, glass sheets, and metal parts during firing processes.

2. Heat treatment furnaces: Cordierite-mullite slabs are used as shelves or supports in heat treatment furnaces where materials need to be exposed to high temperatures for processes such as annealing, sintering, or tempering.

4. Industrial kilns: Cordierite-mullite slabs are utilized in various industrial kilns, including tunnel kilns, roller kilns, and shuttle kilns.