PRODUCTS

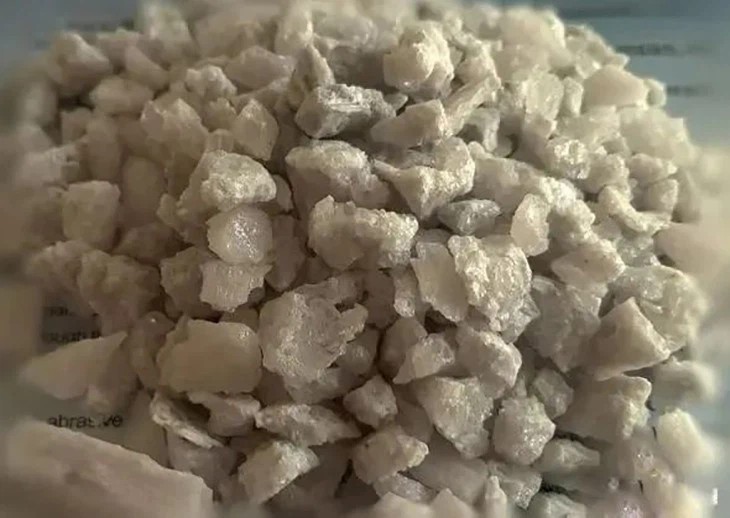

Magnesia Alumina Spinel

Magnesia-aluminum spinel is a spinel refractory material synthesized by high-temperature calcination with magnesium oxide and aluminum oxide as raw materials. This raw material is rarely found in nature, and almost all industrial magnesium-aluminum spinel is artificially synthesized.

Composition: Premium materials such as high alumina oxide, magnesium oxide, and silicon carbide, with customizable composition based on client requirements.

Form: Available in powder, brick, board, and castable forms to suit various application needs.

Refractoriness: Standard range from 1200°C to 1800°C, with options for higher temperature customization.

Application Fields: Widely used in industries such as steel, cement, glass, and petrochemicals for furnace lining and insulation.

Packaging: Options include 25 kg bags, bulk bags, and custom packaging solutions compliant with global transportation standards.

Introduction

Our experienced R&D team can customize the material, form, and size according to your specific application needs while ensuring compliance with international quality standards. With rigorous quality control and advanced production facilities, we guarantee products with high refractoriness, excellent compressive strength, and long-lasting durability. Whether you are in the steel, cement, glass, or petrochemical industry, we are your trusted partner, supporting the success of your projects.

For customization inquiries, please feel free to contact us. We will provide tailor-made solutions based on your requirements.

Magnesia Alumina Spinel Details

Products Description

Magnesium-aluminum spinel is an octahedral crystal form composed of equiaxed crystal system, cube, and octahedron. It has no cleavage and good thermal shock resistance. Compared with MgO and Al2O3, MgAlO4 has a low expansion coefficient and low thermal conductivity, which decreases with the increase of temperature. In addition, since MgO and Al2O3 in the formation of MgAlO4 do not change when the atmosphere changes, it is very stable in a redox atmosphere compared with FeCr2O4.

Features

1.High melting point and high temperature resistance: It has a high melting point and high temperature resistance, which makes it excellent in high temperature environments. This makes it widely used in refractory materials, furnace linings, thermal insulation and other fields.

2.Coefficient of Thermal Expansion Matching: Its coefficient of thermal expansion matches that of some metals and other ceramic materials, making it potentially useful in the manufacture of composites, coatings, and more.

3.Good thermal conductivity: It has high thermal conductivity, which is of great significance in heat conduction and thermal management, such as applications in heat dissipation materials and thermal barrier coatings.

Application

1. Refractories: Because of their high melting point, high temperature resistance and chemical corrosion resistance, they are widely used in the field of refractories to manufacture linings, furnace walls, and heat insulation layers of high-temperature kilns.

2. Chemical industry: Magnesium-aluminum spinel has applications in chemical reaction vessels, catalyst carriers, etc., because of its chemical stability, it can withstand many corrosive substances.

3. Heat conduction and heat dissipation: Its good thermal conductivity makes it applicable in the field of heat conduction and heat dissipation, for example, it is used to manufacture heat dissipation materials, heat sinks, etc.

4. Aerospace and automotive industry: Due to its high temperature resistance and corrosion resistance, magnesium aluminum spinel is used in the aerospace and automotive industries to manufacture high-temperature parts, turbine blades, jet engines, etc.